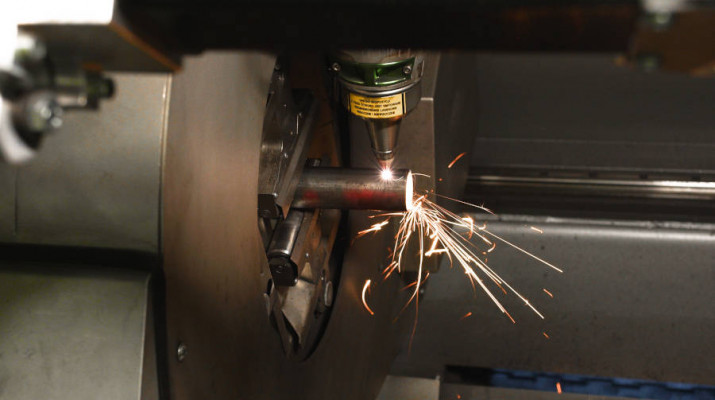

Laser pipe and profile cutting involves using a laser to precisely and quickly cut metal pipes and profiles of various shapes and sizes. In this process, the laser beam is directed at the metal material, and where the laser light is concentrated, the material is rapidly heated and melted. At this point, the cut is made by air, which is injected into the cut area and removes the melted material, allowing a continuous and precise shape to be cut at the same time.

Laser cutting is highly accurate and allows for precise and uniform shapes, which is especially important for many industrial and manufacturing applications. In addition, the laser is able to cut thick materials, such as steel and aluminum, without damaging their surfaces, which is difficult to achieve with other cutting techniques. It’s also worth mentioning that laser cutting is very fast and efficient, which can increase production efficiency and save time and money.

Laser cutting of tubes, profiles and special sections is one of the most important services that allow the production of metal parts with the highest precision and quality. In order to carry out this process, modern metal processing plants use the latest ADIGE LT 8.20 laser cutting machine with Fiber technology.

The peculiarities of this cutter allow cutting materials of up to 6500 mm in length and making finished parts of the same length. The state-of-the-art laser scanning systems used in the cutter make it possible to achieve the highest cutting precision, as well as maintain smooth edges and a clean surface without scratches or chips.

Technologies such as Active Piercing, Active Focus, Active Weld and Active Scan allow faster and more precise cutting of materials with non-uniform thickness. The Active Weld system allows 100 percent repeatability of the correct execution of cutting operations with respect to the position of the welding seam.

The CAM software Artube, Assembler, Part Viewer, Protube Enterprise and Protube Express enables efficient order management, sending production orders to machines, estimating production costs and monitoring the entire production process.

The Protube Monitoring module allows you to track production progress in real time, and the Protube Trace module allows you to track production history and provide production reports.

All in all, laser cutting of tubes, profiles and special sections is a service that allows you to produce metal parts with the highest precision and quality, and gives you the ability to manage the production process efficiently.