PROMOTIONAL MATERIAL

In an era of dynamic technological changes, precision machining forms the foundation for many industrial sectors. TOKAR CNC Technology from Mierzęcin has been delivering high-quality metal components for years, meeting the needs of demanding sectors such as medicine, food industry, and electronics.

Specialization in Stainless Steel Machining

TOKAR CNC Technology specializes in precision stainless steel machining – a material valued for its durability, corrosion resistance, and hygienic properties. Stainless steel finds wide application in sectors that require not only high-quality execution but also reliability under challenging operating conditions.

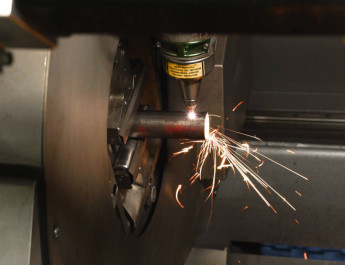

Machining this type of material requires advanced machinery and experience in selecting appropriate cutting parameters. Thanks to modern CNC machining centers, the company can maintain tight dimensional tolerances while ensuring excellent surface quality. This is particularly important in the production of components for medical and food applications, where every detail must meet rigorous quality and safety standards.

The TOKAR CNC Technology team has years of experience working with stainless steel in various grades, including AISI 304, 316, and 430, which allows them to adapt the technological process to specific customer design requirements. The services offered include precision turning and milling, as well as drilling, threading, and grooving of parts with varying degrees of complexity.

Modern Machine Park

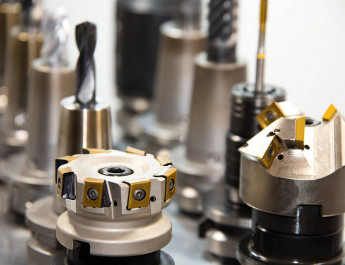

The heart of the company is its modern machine park, which forms the basis for high-quality CNC machining services. Key equipment includes:

- MAZAK CNC Lathes – reliable machines designed for machining parts with diverse geometries, ensuring high accuracy and speed of execution

- STAR Longitudinal Turning Automats – ideal for producing precise, high-volume small and medium-sized components

- Numerically Controlled Machining Centers – enabling comprehensive 3- and 4-axis milling, including difficult materials such as stainless steel and engineering plastics

All machines are regularly calibrated and maintained, operated by experienced CNC operators. This makes it possible to produce even the most demanding components while maintaining the highest repeatability.

Moreover, TOKAR CNC Technology’s machine park is constantly being developed – the company invests in new technologies, process automation, and digital production monitoring systems, which translates into shorter delivery times and even higher precision.

Applications Across Various Industries

Precision components produced by TOKAR CNC Technology find applications in many sectors:

- Medicine – parts for diagnostic equipment, surgical instruments, components for implantology systems

- Food Industry – components for processing machines meeting rigorous hygiene standards

- Electronics – parts for electronic devices and control systems

High Quality and Partnership Collaboration

TOKAR CNC Technology uses only certified materials, and all production stages undergo strict quality control. Technological processes are monitored and documented, allowing for real-time detection of any deviations and immediate response. Every component leaving the production facility undergoes dimensional control using precision measuring tools such as digital calipers, micrometers, and coordinate measuring machines (CMM).

The company has implemented a quality management system based on ISO standards, covering all stages – from material acceptance, through production, to final inspection and packaging. This approach guarantees customers not only excellent execution quality but also full delivery repeatability and compliance with documentation requirements, which is particularly important in medical, electronic, and food sectors.

TOKAR CNC Technology also collaborates with external partners specializing in galvanization and coating application, enabling customization of product finishes to individual customer needs.

Invitation to Collaborate

TOKAR CNC Technology is a company open to new challenges and ready to execute both individual orders and serial production. Competitive prices, timeliness, and experience gained over the years make it a solid business partner.

If you are looking for a proven precision CNC machining contractor – contact TOKAR CNC Technology and see what a modern approach to metal looks like.

Contact Information:

- Address: Mierzęcin 30A, 66-520 Dobiegniew / POLAND

- Phone: +48 575 275 537

- E-mail: sekretariat@tokar.pl

- Website: www.tokar.pl