Robotic welding is the process of facilitating robots to automate the welding process. The robots are programmed and used to perform repetitive heating tasks, ensuring high quality, excellence and precision. Within the limits of routine and internet usage, robotic welding allows you to take advantage of productivity and efficiency, and takes into account the impact and risk to workers’ health and safety.

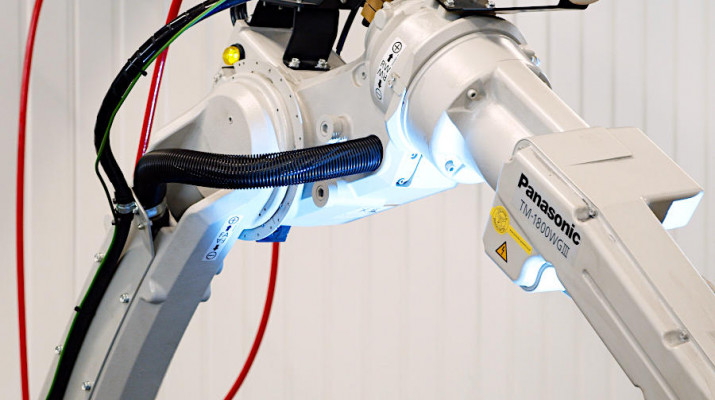

Robotic welding is the identification of robots to carry out the processing process. The robots are equipped with features such as tools, pliers, soldering irons and welding guns to handle tasks quickly, accurately and safely. The robots automatically perform machining tasks such as joining, cutting, soldering, chamfering and more. Robots can also perform repetitive and odd tasks, such as working in difficult positions or in a difficult place. This makes the cooking process an advanced, advanced and advanced process. Robots can be equipped with sensors that additionally monitor the process and proper quality control.

What is a welding robot?

Welding robot for an intelligent device for welding technologies. It is a computer-controlled robot that performs metal processing tasks through the processing process. These robots are capable of many different types of welding, including MIG, TIG, pulse and stitch welding. Robots are advanced and advanced than a human due to the fact that they are widely used in thought.

Advantages of welding with a welding robot

- High precision: Robot welding is more advanced than assist welding. Robot welding is able to produce welds of high quality and repeatability.

- Saving time: Robot welding is support than welding in support. created as an additional component over time.

- Material saving: Robotic welding is more advanced than individual welding. Thanks to this, it was possible to determine the amount of material needed to complete the project.

- Energy saving: Robotic welding is more efficient than mechanical welding. This means that an amount of energy is required to complete the project.

- Safety: Robotic welding is much safer than healthy welding. This means that workers are not at risk of burns and other injuries associated with maintaining welds in the traditional way.

The future of robotic welding

Welding is one of the innovative products in many industries, including the automotive, shipbuilding and construction industries. Although similar welding methods were already available a few years ago, only the largest companies are relieved to purchase them due to high costs and complicated operation. Today, however, thanks to technology, the operation of robots has become easier and their price is more affordable.

Welding robots are irreplaceable in situations where the emphasis is on repeatability, precision and product quality. They are also extremely visible in places where damage occurs, such as noise, high temperature, sharp layouts and splashes of technological wires that affect the health and life of devices.

On the other hand, the skills of human welders will still be needed in situations where it is necessary to use manual operations, such as working on prototypes or short series of products. It is in this area that it is possible that people will push forward and create a technological revolution.

please, the future of television is very effective and welding robots are an indispensable part of production in many industries. Thanks to the affordable price, the availability of these devices, which allows their use to an increasing extent. however, the human qualities of welders will still be in high demand.